Keys to Designing Effective Chemical Feed Skids

Engineering Reliable Skids Starts with Proper Assessment

Chemical feed skids are critical components of industrial processes that require the precise delivery of chemicals to maintain efficiency and safety. Designing the right chemical feed skid for your application is essential to ensure that it can meet your process requirements and deliver the necessary chemicals in a controlled and consistent manner. In this blog, we will discuss some important factors to consider when designing a chemical feed skid for your application.

Collaborate with Modus Engineered Solutions

Improve operational efficiencies and compress time to market by leveraging innovation.

Chemical Compatibility

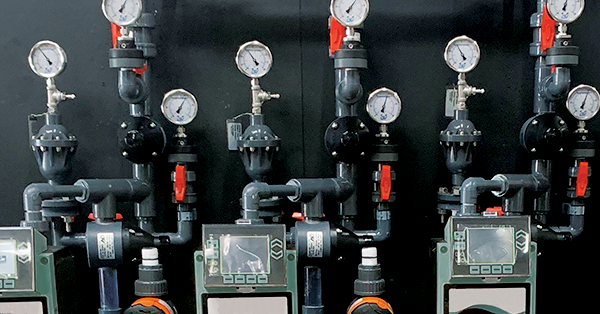

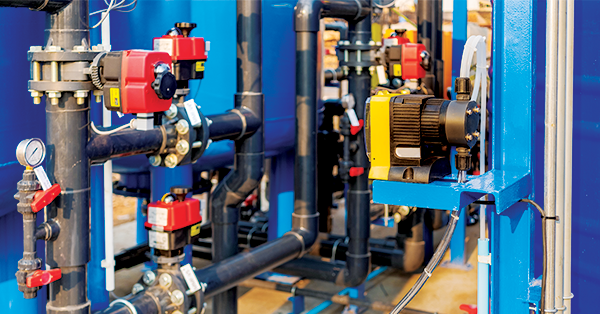

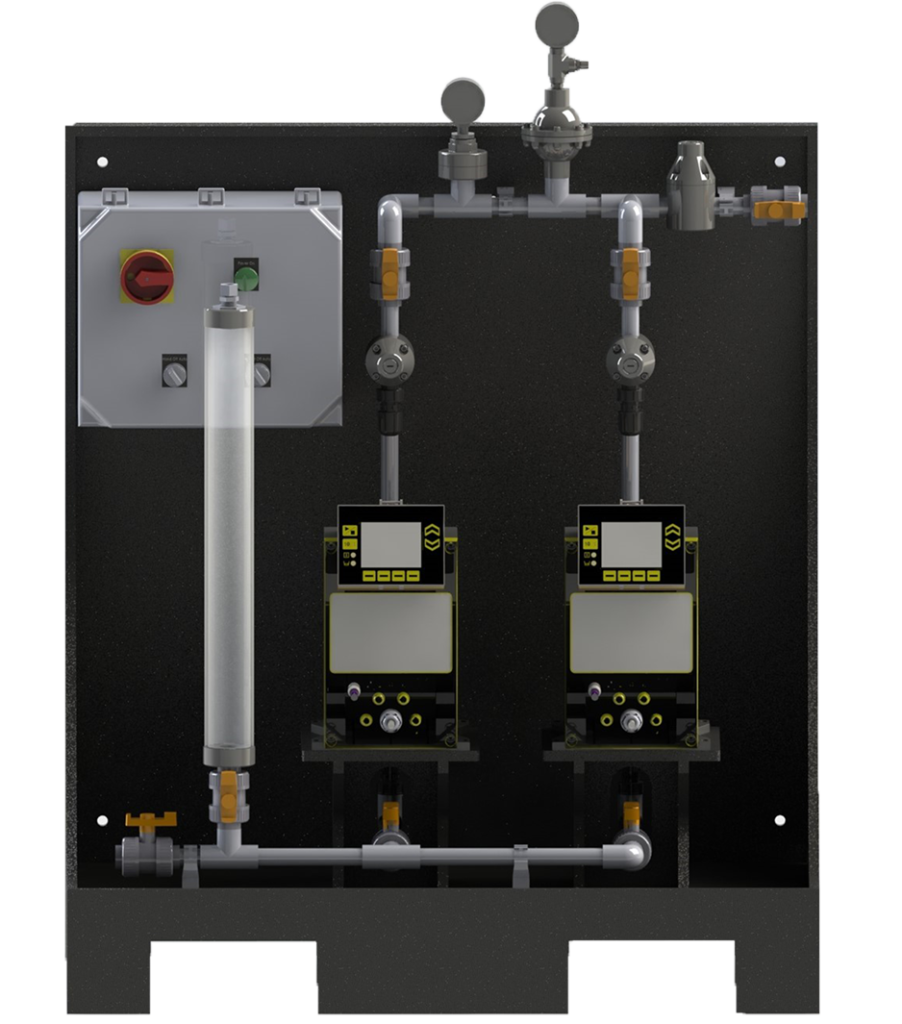

One of the most important factors to consider when designing a chemical feed skid is chemical compatibility. Chemical feed skids are typically designed to handle a specific range of chemicals and concentrations, and it is essential to ensure that the skid components, including tanks, pumps, and valves, are compatible with the chemicals being used. The most common materials used in chemical feed systems include PVC, CPVC, stainless steel, and PVDF. Keep in mind, some chemicals can react with certain materials, such as metals or plastics, and cause corrosion or other damage to the skid components, which can lead to process downtime and safety hazards. Therefore, it is crucial to identify the proper materials. We recommend consulting with our application engineers at Modus who specialize in chemical metering and other wastewater applications to ensure that the skid components are compatible and reliable.

Operating Conditions

You must consider the operating conditions when building a chemical feed skid such as the required flow rate and pressure of the process stream. These conditions will determine what type of pump, valve, and overall structure of your chemical feed skid and how it will dose the chemicals. The flow and pressure of the chemical source, as well as the required flow rate and pressure of the outgoing process, will determine the appropriate products and structure characteristics of the chemical feed skid. To ensure that the skid can meet the process requirements, it is essential to outline the specific flow rate and pressure, which includes considerations such as the size of the process stream, flow pressure, chemical concentration, and process fluid viscosity. Furthermore, this information will determine pump and valve selections to achieve the required flow rate, and pressure.

Accuracy and Precision

In the previous paragraph we detailed how operating conditions like flow rate and pressure determined product selection and skid structure. Elaborating on that, the accuracy and precision of chemical dosing are tied directly with the flow rate and pressure. Accuracy and precision are critical to the performance and efficiency of any process. Therefore, it is important to design a chemical feed skid with products that will marry the flow rate and pressure to deliver accurate and consistent chemical dosing. Flow meters, pressure sensors, pumps, valves, controls, and other instruments are carefully selected to work in sync to ensure the flow rate and pressure of the chemicals being delivered are accurate and precise. Furthermore, having a team of experienced chemical metering experts who can help guide your decisions with key instruments and skid structure will take the guess work out and bring peace of mind.

Safety and Reliability

Safety and reliability are also critical considerations when selecting a chemical feed skid. Chemical feed skids are typically used to deliver chemicals that can be hazardous to human health and the environment. Therefore, it is essential to ensure that the skid components are designed and manufactured to meet required safety standards and regulations. That is why Modus Engineered Solutions adheres to ISO standards with all engineered chemical feed skids. Additionally, reliability is critical to ensure that the skid can provide consistent chemical dosing without downtime or maintenance issues. As discussed previously, products are chosen based on system conditions, which include chemical compatibility with piping, pumps, valves, and other instruments to ensure system rigor and reliable performance. It is important to select a chemical feed skid manufacturer with a proven track record of delivering reliable and safe skids.

Conclusion

Selecting the right chemical feed skid for your application requires careful consideration of factors such as chemical compatibility, flow rate and pressure, accuracy and precision, and safety and reliability. By working with Modus, a reputable chemical feed skid manufacturer, and consulting with our application and process engineers, you can ensure that your chemical feed skid will deliver the necessary chemicals in an accurate and precise manner, while also meeting the safety and reliability requirements of your application.

Collaborate with Modus Engineered Solutions

Improve operational efficiencies and compress time to market by leveraging innovation.

About Us

Modus Engineered Solutions is the preferred provider of critical service solutions. We leverage the vast experience and knowledge gained across our combined histories to provide exceptional solutions. We don’t just sell parts and service to our customers; we help them realize new and better ways to run more efficiently.

Copyright © Modus Engineered Solutions all rights reserved.