Polymer Feed Systems

The Modus Polymer Feed System is an easy to use, low-maintenance method of hydrating emulsion polymer using the kinetic work available in pressured city water – the system will produce nearly instant hydrated emulsion polymer ready for use.

Key Features

No moving mechanical parts for simple operation.

Compact wall mounted units free up valuable floor space.

Units typically ship within one week for a quick turnaround.

emulsion polymer from 1.0% through 0.2% ranges with no limit to the volumes that can be hydrated.

Polymer Feed Made Easy

Hydrating and Activating Emulsion Polymer

The applications that do not require a 24-hour operation are a perfect fit for the Auto-Flushing system that offers the advantage of automatically flushing out the system prior to start-up and neat polymer introduction. At the end of the run but prior to the hard shutdown, the neat polymer pump is shut off but the Modus Polymer System continues to flush with water. After the system is flushed clean, the water valve is automatically shut down.

These applications are ideal for the Automatic Benchmate System, which offers the advantage of hydrating polymers at a know flowrate and sending them to an integral storage tank. A second metering pump will vary the polymer input into the system manually or via a 4-20mA signal.

Applications with 24/7 opreation requirements will benefit from a wall mounted Modus Polymer Feed System and metering pump combination that hydrates emulsion polymers and convey them into the water system directly and continuously. While aging helps improve polymer efficiency, no aging is required for polymer exiting Modus Polymer Feed System.

Configurations

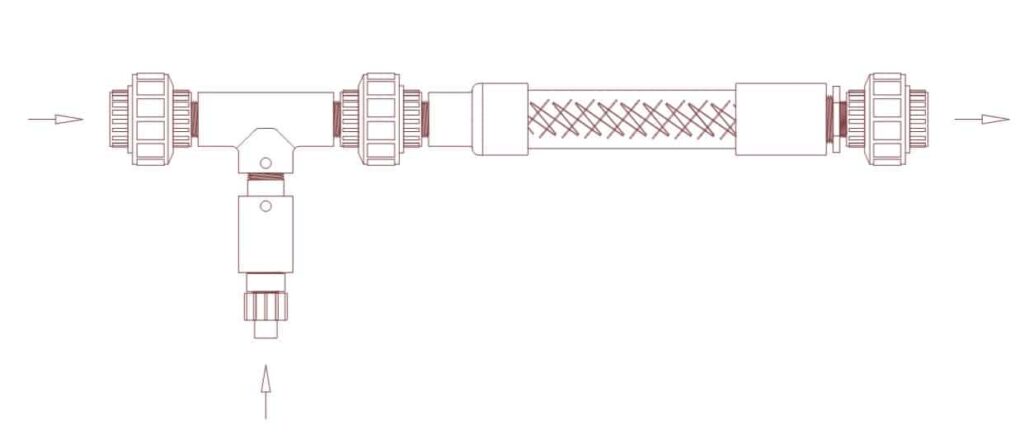

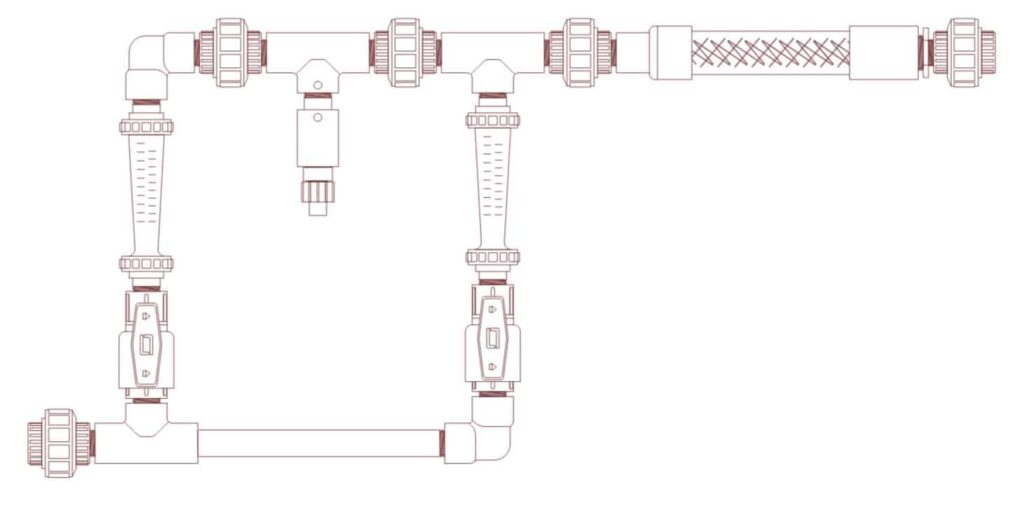

Our popular Modus Polymer Feed Systems incorporate either one or two flowmeters to regulate the flow of the system water supply, followed by our unique Injection Module and a specially prepared Static Mixer. The flowmeters control primary make-up water flow or secondary dilution water when needed. The Injection Module converts pressure into workforce, speeds up the primary flow, atomizes the polymer (providing an emulsion break when called for), and is the first mixing stage of the system. The Static Mixer is the second of the two mixing stages, where the individually trimmed mixer elements help to minimize fouling while blending and re-seeding the product to activate it for your application.

Single Flow Meter Model

2 Flow Meter Model

Choosing The Polymer System for Your Application

All Modus Polymer Feed Systems can be specified to activate polymer from 1.0% down to 0.2% and in mL/minute, parts/million, or gallons/hour. The chart below will help you choose the best Polymer Feed System for your application.

Request a Quote

Our water treatment experts are ready to help answer your questions and provide quotes for your next project. Fill out the form below and we will contact you with one business day.